Avoiding potential issues in additive manufacturing with high-performance materials

By Dr. Zach Murphree, Vice President Technical Partnerships, VELO3D

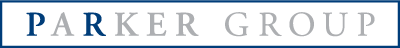

Image 1. (Right) Hastelloy X engine combustor and (left) inside view of its complex interior. Thin air foils and smooth lattice helps the combustor effectively atomize fuel prior to combustion. With traditional manufacturing, this specific part would have required the assembly of 61 discrete components, but 3D printing consolidated it into a unified geometry with fine details and features that are unattainable via any other method. Photo courtesy of VELO3D

Superalloys, as their name implies, have powerful material qualities that extend beyond those of the usual metal combinations. The traditional alloy bronze combines tin with copper, melts fairly easily and is relatively malleable—but has limited industrial use these days. A mix of nickel, chromium, iron and molybdenum, on the other hand, produces Hastelloy X, a superalloy that is formable and weldable, yet provides an extremely high melting point, superior mechanical strength, low creep and long-lasting resistance to oxidation and/or corrosion.

Elwood Haynes created a range of nickel-molybdenum alloys starting in the early 1900s, including the Haynes Stellite Alloy that became the patented Hastelloy X trade name. The nascent aviation industry was thrilled with the robust properties of the new superalloy; Pratt & Whitney used it in the jet engines that powered the first Boeing 707 aircraft in the 1950s. Hastelloy X (HastX) has since become a material of choice for important gas-turbine, hot-section components in aerospace as well as a variety of high-temperature/high-corrosion oil and gas and energy applications.

These applications can include transition ducts, combustor cans, spray bars and flame holders as well as in afterburners, tailpipes and cabin heaters. HastX is recommended for use in other settings, such as industrial furnaces, due to its unusual resistance to oxidizing, reducing and neutral atmospheres. In the chemical process industry, it is used for retorts, muffles, catalyst support grids, furnace baffles, tubing for pyrolysis operations and flash drier components.

The long-wear characteristics of HastX extend product lifetimes. For example, jet engines are frequently driven to overhaul when combustor components wear out due to excess corrosion or cracking. Hast-X provides better corrosion and creep resistance at very high temperatures compared to some other superalloys that see such resistance diminish over time when exposed to extreme heat. Using HastX in jet engine components can thus significantly prolong time between engine overhauls.

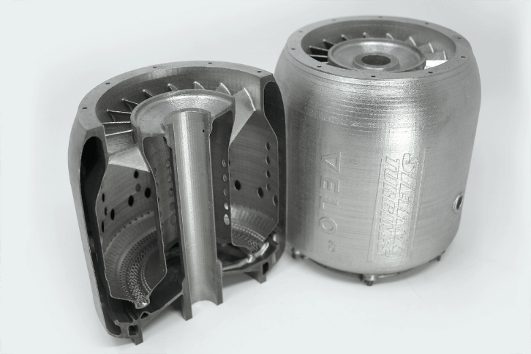

Image 2. Turbine blade 3D printed out of Hastelloy X. Photo courtesy VELO3D

Industry looks to 3D printing for innovative alternatives to traditional methods

With such material considerations in mind, aviation, aerospace and heavy industry have now begun looking at additive manufacturing (AM, or 3D printing) of superalloys as a potential game-changing technology.

AM can deliver complex, previously un-manufacturable, innovative designs that boost product performance while reducing supply chain delays and associated production costs. Particularly in high-temperature gas turbines, which are traditionally assemblies of tens-to-hundreds of parts—including tubes, flow paths, and sheet metal structures that must be formed and welded to other components—AM presents some highly attractive opportunities for design simplification and part consolidation.

Given the desirable qualities that superalloys can deliver, it’s perhaps not surprising that companies that are beginning to explore the potential of 3D printing are asking for AM equipment—or access to contract manufacturers running the more advanced industrial 3D printing systems—that can handle such material.

AM system makers, in turn, are embracing the opportunity to use their technology to solve problems that engineers are encountering when using traditional manufacturing to make high-performance, mission-critical components out of superalloy materials. Response to this consumer demand for new ways to make better parts quickly needs to come in the form of the highest-quality results. But there are inherent challenges to getting the superalloy 3D-printing process right.

Fine-tuning the process of printing superalloys

Metal additive manufacturing is essentially a micro-welding operation in which a geometry-directed laser beam melts ultra-thin layers of material together sequentially to build up a three-dimensional part. Obviously, the purity of the material plays an essential role. While many OEMs have their own recipes for metal powder, quality standards still allow for a range of certain elements within an alloy, which means there can be more or less oxygen, or carbon, in a superalloy formula. In the case of HastX, lower carbon content leads to better results; the most successful print runs occur when material choice controls for that.

Another issue related to the material is that it can throw off base-metal soot or condensate during the laser-sintering process, fouling the surrounding powder. If the soot lands directly on the powder bed it can cause issues with energy absorption. Or if the gas flow used to flush out the chamber during AM doesn’t completely evacuate the soot, the chamber volume can become loaded with airborne condensate that blocks the laser beam itself. Such occlusion changes the amount of power being delivered to the powder bed and interferes with the welding process.

To ensure clean gas flow around a part being sintered from HastX, next-gen AM systems operate in an argon-gas environment that keeps oxygen levels extremely low. Some other systems use nitrogen but, particularly for aerospace applications, argon is preferred because it delivers better quality results throughout a build.

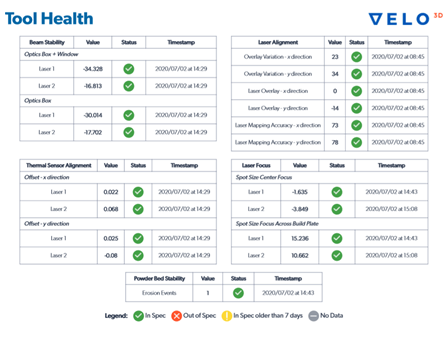

Another issue with HastX can be hot-cracking, which is less of a problem than with some other superalloys but is still something to be controlled for. Particularly in the case of the kinds of thin-walled, high-heat structures for which the use of HastX is optimum, directing the thermal energy of the laser very intentionally is key. It’s critical to do this, because how the active meltpool cools down and solidifies during an AM build is dependent on what’s around it—usually metal on one side and powder on the other.

Powder is an insulator that doesn’t conduct heat well so, as a layer cools, that thermal energy predominantly goes into the newly created, thin metal walls. Too much thermal energy in the wrong place can weaken and warp the structure. Therefore, it’s critical that the laser power be applied at the precise location and strength every millisecond—something the newer AM systems’ in-process monitoring and feature-specific parameter controls do. This precision has dramatically reduced cracking issues often associated with HastX.

Image 3. Machine health snapshot from a next-gen AM system’s software build report, showing that all critical sensors are calibrated. Laser alignment, focus, and beam stability are essential to monitor and sustain throughout the 3D-printing process of any material. Image courtesy of VELO3D

Targeting the material to the application

Given the variety of challenges inherent to matching materials to production processes, it’s interesting to note that quite a few AM machine makers now have portfolios of up to 40 different materials, from aluminum to superalloys. Yet, in many cases, the cost of printing doesn’t align all that well with the material chosen. The application space can also be limited.

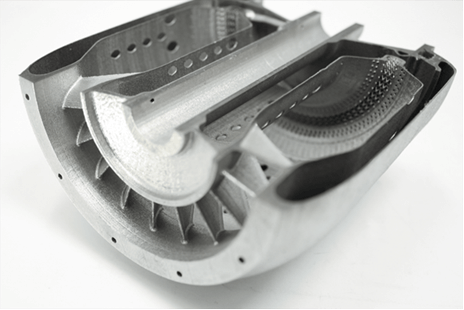

Prioritizing customer and market considerations in the choice of materials for which their machines are calibrated, the makers of the newer AM systems have consciously limited the range of applications for which they’ve developed their exacting 3D printing processes and accompanying software. Capabilities such as support-free manufacturing (at angles now down to fully horizontal overhangs) of extremely thin-walled parts align well with high-temperature applications involving fluid flow and heat exchange—in turn lending themselves extremely well to the production of parts and components made from superalloys like Hastelloy X.

Image 4. Closeup of cross section of turbine combustor, 3D printed as a single component with Hastelloy X superalloy. Photo courtesy of VELO3D

For mission-defining 3D printed components, a combination of innovative geometries and high-performance alloys is a now-available game-changer for improving industry competitiveness.

HASTELLOY is a trademark of Haynes International, Inc.