An Englishman, a Swede and an American who grew up in Ecuador met in Providence, Rhode Island—sounds like a humorous opening line, but it’s actually the beginning of the story of ABAQUS software.

In 1968 the Englishman, David Hibbitt, was a couple of years into his Ph.D. in solid mechanics at Brown University in Providence when he switched advisers to work with Pedro Marcal, a young assistant professor who’d arrived from London with two boxes of punch cards containing a version of the SAP finite element program. Pedro was trying to extend the program to model nonlinear problems including plasticity, large motions and deformations; David had recently discovered Fortran programming and found that he liked writing code, as well as the challenge of applying solid mechanics to engineering design.

David Hibbitt on his Vincent Black Shadow, 1964

At the time people had already recognized the potential of finite element methods, and several commercial codes were available. “But the nonlinear area was pretty wide open,” says Hibbitt. “There was plenty of promise for useful application.”

First foray into the nonlinear realm

Hibbitt’s thesis was funded by a U.S. Navy contract that called for the development of a finite element capability to model the multi-pass welding of submarine hulls and predict the loss of performance caused by residual distortion. So he had to develop heat-transfer capabilities that could handle the latent heat effect when molten metal solidifies, use those temperature predictions to model the mechanical response of the structure, including plasticity and creep, throughout the multi-pass welding process, and then do a buckling analysis of the distorted structure.

“That was a tall order,” says Hibbitt. “And well beyond the capabilities of the computers in those days.” Brown University had one IBM 360/50 computer for the whole campus, which meant limited time parceled out to researchers. Moore’s law tells us that a single cell phone today has the compute power of 33 million such machines. And, as you well know, Abaqus and other codes need far more processing power than a cell phone.

As the research progressed, Marcal’s academic group was increasingly receiving calls from various industries asking whether his new code (Marc) could help them. Enough business started coming in that he incorporated Marc Analysis in 1971, with Hibbitt as a minor co-owner and the first full-time employee. As the company grew, Paul Sorensen (the American in our tale, who had come to the U.S. from Ecuador as a teenager) joined the group for a time but then left to do a doctorate in fracture mechanics, after which he began working at General Motors Research Labs in Detroit.

Control Data Corporation (CDC) supplemented the group’s computer resources by letting Marc run on the mainframes in their data centers on a “pay per hour” basis. A CDC support analyst in the data center in Stockholm, Sweden—Bengt Karlsson—started using the code, and found it intriguing enough that he asked to join the company. He was hired. When Marcal moved to California to take the business in different direction, Hibbitt and Karlsson stayed in Rhode Island with the finite element group. But they found it difficult to satisfy the needs of engineers with design responsibility who had no time to rebuild or debug what was still really a research code for each application. “We thought the sensible way forward was to develop a robust ‘black box’ tool for engineers needing to do nonlinear calculations to solve industry problems,” says Hibbitt. But Pedro had no interest in such an investment.

Creating an all-new code

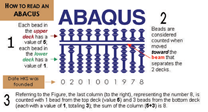

So David and Bengt decided to try on their own. “Almost everyone whose advice we sought told us that we would fail,” David remembers. “There were already 22 viable FE programs out there, competing for industry business, and even the largest computers were too limited to do nonlinear calculations of practical size.” But they had enough in savings to feed their families and pay their mortgages for a year. And so the ABAQUS software was conceived. There’s a message in the company’s first logo, a stylized abacus calculator: its beads are set to the company’s official launch date of February 1, 1978 (2-1-1978).

A lot of tech startups begin in garages; Hibbitt and Karlsson had the relative luxury of the front parlor of the Englishman’s early 19th century Rhode Island farmhouse, plus the dining room table at which David’s wife Susan paid the bills and did the typing, using a rented IBM Selectric typewriter.

“We were a software company with no software, no computer, no customers or prospective customers, and almost no money,” says David. They first wrote a User’s Manual with the goal of making it easy and intuitive to put a problem definition together, then designed the code’s architecture. Hibbitt often wrote code on airplanes while commuting to teach a graduate course in plasticity as an adjunct professor at the University of Texas in Austin—a job he took to bring in some revenue to the starving company.

In line with their shared philosophy of creating practical code to solve real-world problems, Version 1 was created for a specific client. Through a chance meeting at an ASME conference, Hibbitt made a contact at the Hanford nuclear development site lab, which needed to design the mechanical restraints for the core of a prototype fast breeder reactor.

“We knew that if we didn’t deliver code to them in three months we wouldn’t get paid,” says Karlsson. “That was a big incentive!” On time, they delivered 15,000 lines of FORTRAN with just four elements—beam, gap (point contact), truss and SPHEX (to model the deformable section of the fuel rods where the come into contact)—and modeling the thermal expansion, creep, and irradiation swelling of the metals in the fuel rods and restraints.

When Paul Sorensen came back to Providence for a Christmas visit with his in-laws he visited David and Bengt and, over a weekend of discussions with them and (separately) with his wife Joan, chose to join them. So the company became HKS—an amalgam of their three surnames. Paul’s background in finite element simulation of steady-state crack growth was a plus for the work on behalf of the company’s first customers.

Another early client was Exxon Production Research, which needed a code for offshore piping installations and marine riser analysis; this became the predecessor to the ABAQUS/Aqua capability. “The technical difficulty was the relative slenderness of the 10-inch pipes that were hundreds of feet long,” remembers Hibbitt. “The usual stiffness-based beam elements could not handle this in the context of the large motions involved. So we investigated the use of mixed, ‘hybrid’ formulation elements.” The hybrid beam and drag chain elements that were essential to the success of this kind of analysis are still in use today.

Customer projects build up the code

ABAQUS’ capabilities continued to grow during the 1980s along with the number of HKS employees. Shell and continuum elements were added, along with simulation of plasticity, dynamics, heat transfer, and more. “Every customer was important to us and their requirements drove our development,” says Karlsson. “But we were always aware of the need to deliver useful capabilities for specific applications while keeping the code general-purpose.”

In those days HKS personnel would physically install their software at a customer’s site whenever a new license was purchased. They’d bring the source code on tape to the customer’s location, compile the program and make it work on that customer’s computer, run all the examples, and then check the printed output against microfiche copies of the results from previous versions of the code.

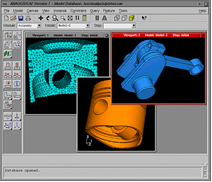

The advent of the first supercomputers sent punch cards to the history books as Abaqus developed a reputation as a sophisticated scientific and engineering software application that could run on these then-powerful machines. As current simulation users now know, the future would bring an explosion of high-performance computing (HPC) that fed the evolution of each new release of ABAQUS, with models leaping forward in the numbers of elements and degrees of freedom, tremendous speed-up in processing time, and increasingly realistic, 3D visualization.

Back in the 1970s, of course, FEA was still in its infancy by today’s standards. For HKS, the market for robust, “industry strength” nonlinear analysis was already there. Nuclear power continued to be an early source of work, with challenges such as nonlinear pipe whip and the development of “elbow” elements to include modeling of plasticity and creep in pipe bends in a computationally efficient manner (considered to be one of the “crown jewels” of the ABAQUS flagship finite elements). Other pioneering mechanics development work included special elements and material models for soils analysis, and modeling of concrete and rebar for analyses of civil engineering structures and nuclear power-plant containment buildings.

The before and after of FEA processing

As ABAQUS’ capabilities grew, it became clear that it couldn’t continue as an independent product without a preprocessor to formulate the problem and a postprocessor to review the results graphically.

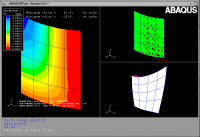

In the earliest days of FEA, engineers had to draw conclusions from their analyses by studying printed tables of their results. Looking towards the future, however, the ABAQUS 4.0 User’s Manual suggested that “the presentation of results in graphic or pictorial form provides for greater insight, for most problems, than columns of numbers.”

To meet this need for result images, the concept of the “plot output file” was born. With this mechanism, users inserted plot commands requesting contours or displacements at intervals during the analysis, and a plot file was generated and displayed on a Calcomp plotter.

A major graphics breakthrough occurred when Hibbitt had the idea of a “neutral” plot file, which was implemented during an installation at ABAQUS customer Electric Boat. This contained device-independent plot commands that were converted into device-specific commands by drivers. Drawing a simple line involved commands to select a color, position, lower, reposition, and then raise the pen. Image files were then displayed on pen plotters or Tektronix terminals; back then it took take half a day for a job of just a few hundred elements to run.

In 1987 ABACUS/Post was released as a standalone postprocessor with command entry and the satisfaction of onscreen, visual feedback.

Developing a preprocessor was a challenge that engaged the ABAQUS team for years. “We wanted a fully interactive code,” says Hibbitt. “We felt that a ‘clean sheet of paper’ approach was the best long-term investment for fully developing our product’s strengths.” The company devoted significant resources to ABAQUS/CAE, which was intended to be the window into the solvers, making it easy to create, manage, and visualize complex simulations and to customize ABAQUS for specific applications.

Explicit, Viewer and GUI customization

At the same time that pre- and postprocessing development was underway, considerable effort was also going into a commercial explicit dynamics code, which had to have its own architecture. Remembers Hibbitt, “Our main target for ABAQUS/Explicit back then was crash analysis. But because—unlike some of the competition—we were very careful not to trade quality of mechanics for speed in computing, ABAQUS/Explicit also proved useful for events like drop test simulation, to ensure that a mobile phone could survive being dropped, for example.”

The first official release of ABAQUS/Explicit was hand-delivered to MIT in 1992. Version 0 of ABAQUS/Viewer was released as a standalone product in 1998. The same features were made available as the Visualization module of ABAQUS/CAE in 1999. Users could now interact with ABAQUS/Viewer through a graphic user interface (GUI), selecting actions and options via icons, menus, and dialog boxes.

Once again, a customer relationship contributed to the rollout of these improved capabilities. In 1996 HKS had entered into an agreement with British Steel to deliver a customized roll pass design system. The project had a profound effect on development activities and was instrumental in driving plans and deliverables for the CAE and Explicit products. It also spurred an integrated approach to development, which impacted both the code architecture (particularly the output database) and the organizational structure, and was also the first to take advantage of GUI customization.

One of the goals for British Steel was to capture the knowledge of their expert engineers and analysts (some of whom were close to retirement) in an automated system that could be used by designers. GUI customization created applications that provided user interfaces in terms that designers were familiar with, while hiding the details of the analyses that take place behind the scenes. This was an important part of the process automation strategy—to enable customization that allowed less-experienced users to access and apply FEA software.

After 23 years of leadership, David Hibbitt retired in 2001; Bengt Karlsson and Paul Sorensen followed suit in the following year. All three are still living in New England. In November 2002 HKS, Inc. changed its name to ABAQUS, Inc., just before the company’s 25th anniversary. Three years later ABAQUS Inc. became the beginning of the SIMULIA brand of Dassault Systèmes. Some 350+ SIMULIA engineers and programmers are now based at the brand headquarters in Johnston, Rhode Island, with another 1350 in 22 countries around the world who serve customers ranging from industry-leading OEMs to tech startups operating solely on the cloud.

Diversifying into Multiphysics

“We used to joke a few years ago that we didn’t really need to develop another finite element, as we already had about 350 of them in the code and didn’t need a 351st,” says Alan Prior, Senior Director, Technical Sales. “But we had to diversify beyond Abaqus [written in lower case letters since 2005] into wider physics, and we had to democratize simulation to a wider range of users because otherwise we’d be self-limiting.”

Today, forty years of Abaqus FEA technology remain at the core of an expanded cornucopia of leading multiphysics capabilities. Starting with the Engineous software’s Isight in 2008, SIMULIA has added capabilities in optimization, template creation and process automation, CFD, injection molding, fatigue and durability, topology optimization, electromagnetics, vibroacoustics, and more.

“The attraction of Abaqus has brought in all these other products that have been developed with the same sort of passion as the founders of HKS,” says Prior. “We’ve acted as a magnet for other technology companies with a similar philosophy.” That shared enthusiasm for taking on the toughest simulation problems is foundational for every company that joins the SIMULIA family, he says. “But we never lose sight of the ‘why’—we always see the value for a customer, or an industry, or the engineering community as a whole.”

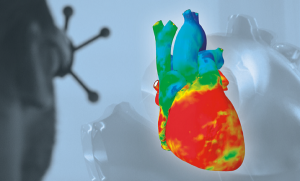

That “why” was reintroduced to David Hibbitt recently when Steve Levine, the leader of SIMULIA’s Living Heart Project, had the opportunity to put 3D glasses on him so the Abaqus founder could view the company’s flagship 3D model of a beating human heart, complete with blood flow, electrical activation, cardiac cycles, and tissue response on the molecular level.

Hibbitt’s response? “This is a wonderful example of what we hoped for as a result of Dassault Systèmes’ acquisition of Abaqus: the delivery of highly sophisticated mechanics, packaged for use by someone with responsibility for a product or process who knows nothing of the complexities buried within the software. In this case that user is a cardiac surgeon, who now has a tool to plan his work specific to the needs of each patient and so dramatically improve his ability to do good…

“Clearly there is plenty still to do to deliver the full value needed for this application. But how wonderful to continue spending your time on such endeavors. We wish you well as you pursue them.”