By Philip Sperling, Product Manager Additive Manufacturing, Volume Graphics

No manufacturing process that becomes a standard remains unchallenged for long. Either remaining weakness and costs of operation get addressed through continuous improvement to the core process, or competing technologies that are upping their own speed, quality, costs—and viability, step in. This is certainly true in Additive Manufacturing (aka 3D printing) where Laser Power Bed Fusion (L-PBF) is prominent and approaches such as Metal Binder Jet (MBJ) and other metal additive methods seek to expand beyond their niches and make gains in series production.

Today, at private R&D sites and on open factory floors, AM systems are evolving at a fierce rate, pushing to dominate a specialized sector or serve someday as a universal tool, such as that filled by Computer Numerical Control (CNC) machines. No manufacturing process is static, and AM is witnessing great change and progress.

Enter Metal Binder Jet technology

Metal Binder Jet (MBJ) “layering” technology is a quickly emerging approach. Like the industrial leader L-PBF, it promises new performance and functionality and higher productivity within its target markets. It also hopes to provide the same manufacturing agility and to complement traditional shape-forming and finishing processes. MBJ at present typically utilizes stainless-steel 316L and 17-4 PH to address performance goals for industries such as automotive, aerospace and hydraulic or pump components.

To restate a point: the AM industry is changing and improving at a blistering pace, both in the speed and size of parts made, their geometrical and metallurgical accuracy, and their repeatability for quality and volume manufacturing. Traditional lists of strong “advantages” and “disadvantages” are expected to change as improving AM technologies expand capabilities and grow past their entry markets.

For instance, the argument about support structures in L-PBF being a key disadvantage, while generally true, is not all inclusive. A new generation of advanced and available L-PBF systems have nearly negated this issue with potential zero-degree wall angles, achieved through careful, end-to-end process control.

Porosity is a common challenge and “pass-fail” measurement for all AM systems. But in most cases, AM systems provide better part density than castings. MBJ, at least in some quarters, is on a rigorous path to address porosity and related stresses through use of CT scanning and software analysis.

The role of CT analysis in MBJ development

CT analysis provides insights at every phase of product development and manufacture. Because of its ability to view interior regions of a part non-destructively, it provides valuable quantitative data on both specific, critical and overall regions of a part and assembly. High-performance AM components usually exhibit fresh and quite novel geometries. There are unique stresses and vulnerabilities inherent in creating purely function-driven passageways and features, be it with L-PBF or MBJ systems.

Unlike the laser-induced heat approach of L-PBF, MBJ is driven by the interaction of powder particles, the compaction by the roller and the application of the adhesive binder. Parts are later heat cured in a two-step process to burn off the binder additives, reduce porosity and achieve target strengths and desired quality. In the first “colder phase” the green part is debindered. Next, a higher temperature is applied (usually in the same oven) to sinter the part to its final strength. Achieving a strong green part is crucial in the first stage to remove excess powder and allow for handling of the green part within the sintering stage.

With all evolving and even mature AM technologies, on-going process knowledge and inspection, and final control, are paramount to success. In order to reach commercial reliability, every approach has had to move away from black-art practices and “recipes” that can’t be replicated machine to machine, or even batch to batch on the same systems. Here is where CT analysis can help developers understand process causality and interrelated factors that influence outcomes. Pinpointing causes and effects can serve to aid in the use and development of sensors, feed rollers, printheads, feeders, binders, and overall operating parameters. Analysis helps greatly in effectively addressing shrinkage, distortions, brittleness and porosity.

Early process parameter development.

Early insight into print-process behaviors and conditions that lead to observable, measurable, trial outcomes is crucial for shortening development cycles and establishing long-term operating parameters that are reliable, and deliver the highest productivity and commercial success. Reaching results faster in early development helps compress all the follow-on stages of product creation. It also establishes a sound methodology for continuous improvement and future expansion of system features and capabilities.

CT analysis enables a deeper understanding in the development of MBJ process parameters, e.g., when the user is evaluating different combinations of powder, layer thickness and binder saturation. Other testing methods are very limited and don’t give a deep volumetric insight into the green part.

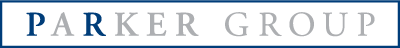

Image 1: Low-resolution scan showing (90µm and 30µm) layer thickness of a green MBJ part. Analysis reveals distinction between layers, different compactness, porosity, and high-density material accumulations—ahead of the debindering and sintering process.

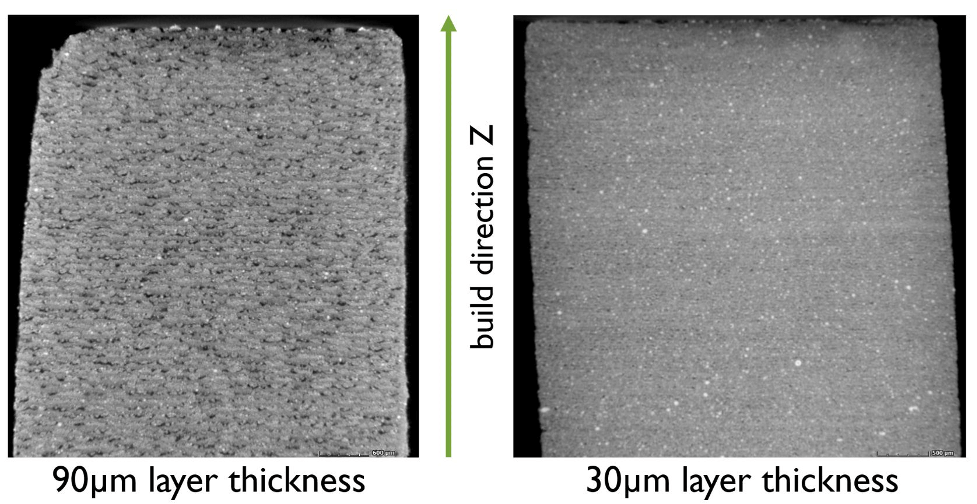

Image 2: Low-resolution CT scan of the just produced green MBJ part showing horizontal lines corresponding to spacing of the print head nozzles; voids created by impact of droplets; and, for 90 µm layer thickness, 3x larger amount of binder—causing a downward flush of finer particles from the top to the bottom layer.

One interesting effect identified through CT analysis of MBJ parts has been the tendency for segregation of fine powder particles in the bottom layers of a print, which leads to higher porosity. This problem is caused by the action of finer particles to sometimes agglomerate. Understanding this behavior allows engineers to evaluate original powder sizes in relation to layering methods and binder mixes.

For development of early, critical system parameters, low-resolution CT slice images have been shown to be excellent for overview and initial analysis. High-resolution CT slice images were comparable to microsection images and were good for targeted analyses. 90 µm layer thicknesses revealed larger inhomogeneities that later led to poorer quality parts in the post-sintering stage.

Later process parameter development

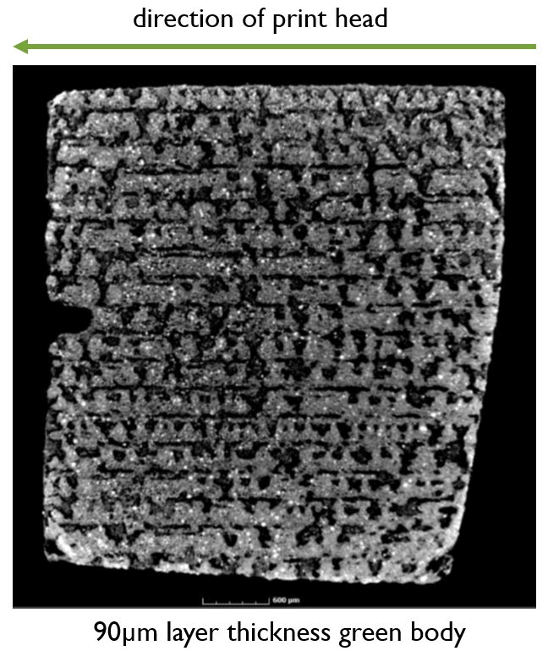

Image 3. Analysis of the XY-plane in red, measures powder density without the binder imprint. The yellow area below it measures the powder density with the binder imprint. The results show the segregation effect of finer particles and the resulting porosity.

Production of MBJ parts entails several stages. These include the initial print (sensitive to layering heights, binder amounts and powder quality); high-temperature debinding (still a highly porous state for the part); longer-cycle, lower-heat sintering to further bond the metal, reduce porosity and eliminate binder additives.

As with early-stage CT analysis, each phase of MBJ part development can be measured via one-off scans, batch or inline automated inspections, according to circumstances such as production controls for aerospace-spec parts.

Together, early and mid-process tracking reveal these main findings:

- Density variations can be observed in MBJ in sintered parts. These variations can be traced back to the powder application by roller, the binder application itself, and the powder-binder interactions

- Binder application can lead to segregation of powder particles in one layer

- The binder application process can lead to porosity in green and sintered parts due to droplet impact. Higher binder saturation levels can compact the particle structure in green parts due to capillary forces and mechanical impact effects

With final part density, strength, and geometric accuracy so important to commercialization—and shrinkage rates and other process impacts affecting quality and yield—in-process inspection and knowledge collection is fundamental to success.

Benchmarking and Prediction

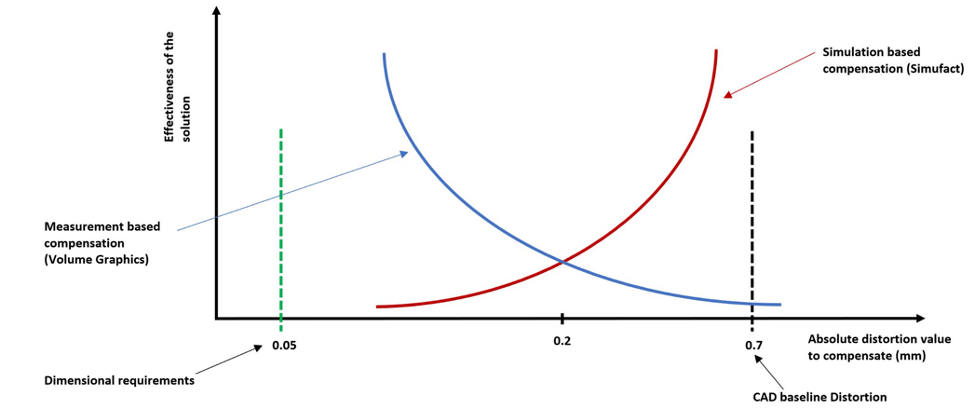

Two compatible CT software analysis approaches can help in early process analysis and geometry compensation. They are measurement-based and simulation-based.

Measurement-based analysis serves to benchmark stages and conditions in the process leading to quantification of approaches and goals, improvements, and establishment of required, final part geometries—including comparing nominal-actual CAD tolerances and geometries against the as-manufactured part to show deviations.

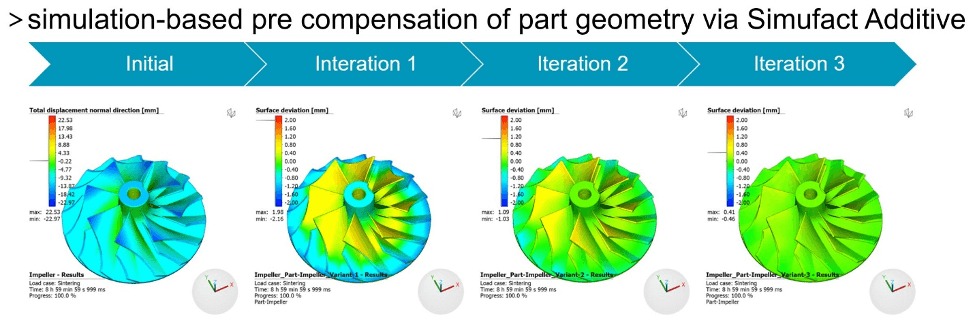

The simulation-based approach relies on prior process simulation of the shrinkage, e.g. in Simufact Additive. In such software solutions, the part geometry and the occurring shrinkage during the sintering process can be simulated and the part geometry can be adjusted to the different shrinkage behavior in the X,Y and Z axes. For more complex part geometries, the simulation-based approach can be used to make detailed adoptions for complex part designs.

Many challenges overall can be addressed using simulation, including shrinkage compensation and process adjustments going back to powder sizes and anomalies in air spaces through to aspects of curing and post-processing.

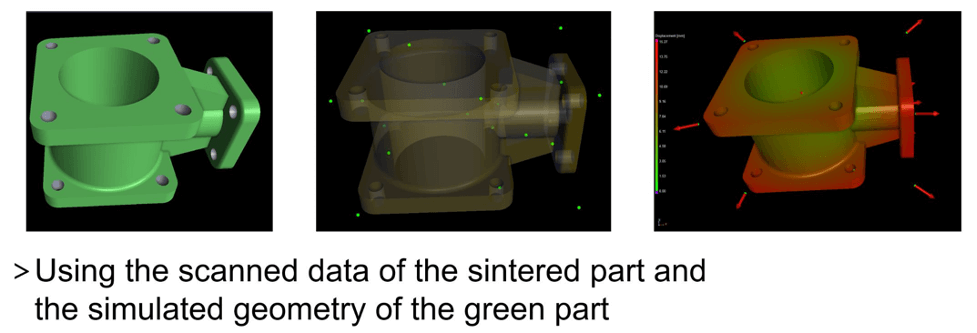

Image 4. This sequence of images (left to right) shows the nominal part geometry, a scan of the sintered part and the simulated geometry of the earlier green part.

Advantages of the measurement-based compensation software approach are, 1) compensation for distortions that are beyond the accuracy of simulation and, 2) the ability to tackle non-uniform distortions within the build space and sintering furnace, providing machine repeatability.

Image 5. Simulation allows individual process stages to be tested virtually and iteratively for design adjustments related to shrinkage, for example, and predictions made of final part conformance to specifications.

Advantages of simulation-based compensation are, 1) predicatively solving manufacturing problems, 2) Identifying an orientation/support concept that is fit for distortion compensation and, 3) the ability to iterate designs free of the cost of physical tests and numerous trial runs.

Image 6. Shows the dimensional requirement set in the CAD model and the absolute distortion rate needing compensation.

A solution for R&D and production

CT software analysis of scanned data for additive processes, such as MBJ, provides the insights and actionable information needed for shaving years off development efforts. It can also help ensure that production examples reach the series quality demanded by customers. In the race to use additive manufacturing for creation of breakthrough designs and much-needed, quickly produced, direct-part replacement markets, CT analysis software offers the depth, breath and level of automation required for advancing new and evolving AM technologies.